rockwell hardness c testing calibration adjustment|rockwell hardness testing machine diagram : ODM The principle of rockwell hardness test Rockwell hardness measurement method is to use rules of pressure head, two trials in successively applied (early test force Fo and total test force F), . 🇧🇷Empresa de Apostas Líder em Reputação Global: Oficial TG: https://t.me/atend09vip Oficial IG: https://www.instagram.com/09vip.vip/ Oficial Facebook: .

{plog:ftitle_list}

web22 de mai. de 2023 · shoptime. TV aberta. Via TV Pop. SIM, da Vivo. SIM, da TIM. SIM, da Claro. SIM, de outra operadora. Ainda NÃO possui 5G. Não sei dizer. Encerramento das atividades de canal de oferta de produtos .

For calibration, you need several test blocks to cover the range you test. An improperly adjusted tester can be correct at one hardness, and off at higher and/or lower .I have a Rockwell C hardness tester that I think needs calibration, when I use the .

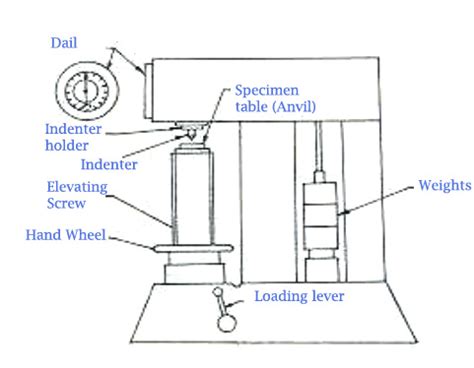

rockwell hardness testing machine diagram

I have a Rockwell C hardness tester that I think needs calibration, when I use the standard provided with it (64.5 +/-1 RC) it consistently reads 62, but since it was indented so many times I had doubts about its .

The principle of rockwell hardness test Rockwell hardness measurement method is to use rules of pressure head, two trials in successively applied (early test force Fo and total test force F), . The purpose of this Guide is to explain the causes of variability in Rockwell hardness test results and to supplenment the information given in test method standards with .This document provides guidance for calibration and testing laboratories involved in hardness measurements, as well as their assessors. It has been produced to improve harmonization in .

2.4 calibration checking Take a test on a test block that is marked for the proper scale with a value that is close to the hardness of the specimens that are to be tested.The Starrett 3814 accurately measures hardness of materials in Rockwell hardness A, B, and C scales. Heat-treated steels are tested using a 120 diamond indenter in the C-scale (HRC 20 .Adjust the starting point using the #8 or #9 key on the keypad so that the surface of the test piece is approximately 1/8” to 1/16” from the tip of the indenter.The use of tungsten carbide balls will provide an improvement to the Rockwell hardness test because of the tendency of steel balls to flatten with use, which results in an erroneously .

this tester uses the standard test method for rockwell and Superficial rockwell hardness testing per AStM e-18. 2.1.1 Basic Operation 1. turn power switch on (back of the tester). the display will read SeLF teSt 2. After a few seconds the display will change to show the scale and status, for example: HrC Set 3.C 150 Kg Diamond Black A 60 Kg Diamond Black B I 00 Kg 1/16" Ball Red F 60 Kg 1/16" Ball Red Remarks For other Rockwell hardness scales see pocket chart enclosed. 9. Remove major load to "sec by rotating load knob {J) counter clockwise. • I 0. Hardness is indicated on hardness indicator {P).-Read black figures when using diamond penetrator.

In the Rockwell hardness test, a differential-depth method, the residual depth of the indent made by the indenter, is measured.In contrast, the size of the indentation is measured in the Brinell, Vickers and Knoop optical test .Phase II Hardness Testers accurately measure hardness of materials in Rockwell hardness A, B, and C scales. Heat-treated steels are tested using a 120° diamond indentor in the C-scale (HRC 20-70). Soft materials are tested using a 1/16" carbide ball indenter in the B-scale (HRB 25-100). Very hard materials are tested using a 120° diamond In manual dial gage testers ASTM correction tables must be referenced to determine the correct factor to adjust by. . Verification should be performed by an accredited verifying agency and the report should follow and reference ASTM E18 Rockwell test method. Hardness testing is an important and useful tool in materials testing, quality .There are two general classes of Rockwell test: Rockwell and superficial Rockwell. In Rockwell testing, the minor load is 10 kgf and the major load is 60, 100 or 150 kgf. In superficial Rockwell testing, the minor load is 3 kgf and major load is 15, 30 or 45 kgf. In both types of test the

ASTM E18 contains a listing of all regular Rockwell scales and typical materials for which these scales are applicable. Use these tables in selecting the scale that is appropriate for your application.Three economical Rockwell Hardness Testing Machines to suit practically every application. • The digital type (HR-430MR and . Fine adjustment table for Jominy test Fine adjustment table for Jominy test Length 16"(400mm) groove width 2"(50mm) For cylindrical specimens . Calibration Set Order No. Order No. 64BAA241 64BAA242 C Scale Set B .

ISO 6508-1:2015, Metallic materials — Rockwell hardness test — Part 1: Test method ISO 6508-3:2015, Metallic materials — Rockwell hardness test — Part 3: Calibration of reference blocks 3 General conditions Before a Rockwell hardness testing machine is verified, the machine shall be checked to ensure that it is

Part No. MA-100 Version 4.4 Rev.01/16 VERSITRON® Rockwell Hardness Testing System Operation Manual BT130R & BT130SPart No. MA-100 Version 4.4 Rev.01/16 VERSITRON® Rockwell Hardness Testing System Operation Manual BT130R & BT130SRockwell correction value for testing cylindrical specimens If a Rockwell test is conducted on cylindrical parts, then, due to the lower resistance of the test surface with respect to the indenter, the following correction values – depending on the specimen curvature radius and the Rockwell scale used – must be added to the test result (acc .

The precision measurement group at Cross offers ISO 17025 accredited hardness tester calibration for both Rockwell and Brinell hardness testers. Our ISO 17025 accreditation covers indirect verification of Rockwell hardness with methods outlined in ASTM-E18 (current version) and Brinell hardness in accordance with ASTM-E10 (current version).Shop Rockwell C Scale, Hardness Calibration Test Block Set at MSC Direct top provider of high quality products. Starrett. Rockwell C Scale, Hardness Calibration Test Block Set-4 Piece. MSC # 83671750 Mfr # 67969. Write the first review. ,644.26. Price. Add to Cart Help. Help. 24/7 Customer Care. 1-800-645-7270;

rockwell hardness testing chart

The Rockwell test is particularly suitable for measuring the hardness of hardened metals and alloys. These materials often have high hardness levels and require higher applied loads to create an indentation. The Rockwell C scale (HRC) is commonly used for harder materials. Hardened Materials The Rockwell hardness test is less affected by .Metallic materials — Rockwell hardness test — Part 2: Verification and calibration of testing machines and indenters 1 Scope This document specifies two separate methods of verification of testing machines (direct and indirect) for determining Rockwell hardness in accordance with ISO 6508-1, together with a method for verifying

1.1 This test method covers Rockwell L scale hardness testing of graphite materials with grain size less than 0.8 mm and a hardness range between 0 and 120. 1.2 Test Methods E18 shall be followed except where otherwise indicated. 1.3 The values stated in .Part No. MA-100 Version 4.4 Rev.01/16 VERSITRON® Rockwell Hardness Testing System Operation Manual BT130R & BT130S

Indenters in a Rockwell hardness test are either hardened steel balls or a conical diamond. Two sets of loads cause an impact on the material surface, which include an initial minor load and a final major load. Additionally, the impact often causes an indentation on the material surface, and measuring the depth of this indentation helps to .Standard Rockwell Hardness Testers which include C, B, and A Scales. To certify your Standard Rockwell Hardness tester to the current revision of ASTM E18, you are required to have certified penetrators. If certified penetrators are not available, we can certify your tester to the previous revision. We offer NIST Traceability on C Scale only.

Rockwell Regular and Superficial Scales Rockwell Regular Scales Rockwell Scales Rockwell Regular and Superficial Scales Machine Dimension (H x W x D) 33 in (833 mm) x 8.75 in (222 mm) x 21 in (533 mm) Standards Compliance/ Accuracy Exceeds ASTM E18-03 and EN-ISO 6508 Power Supply 110/ 120/ 60Hz (optional 220/ 240/ 50) Test Force Application TypeOur A2LA-accredited laboratory is qualified and equipped to calibrate most models of hardness testers, including micro-hardness, Vickers, Knoop, and Rockwell, per the applicable ASTM Standard. Our expert technicians at LTI Metrology will determine the accuracy of the tester during calibration and will make necessary adjustments to bring the tester within the manufacturers’ .Part No. MA-100 Version 4.4 Rev.01/16 VERSITRON® Rockwell Hardness Testing System Operation Manual BT130R & BT130SISO 6508-2:2015, Metallic materials — Rockwell hardness test — Part 2: Verification and calibration of testing machines ISO 6508-3:2015, Metallic materials — Rockwell hardness test — Part 3: Calibration of reference blocks 3 Principle An indenter of specified size, shape, and material is forced into the surface of a test specimen under two

rockwell hardness tester procedure pdf

wankel compression test vs normal piston

Failure to properly prepare and execute a Rockwell hardness test can result in compromised test data or false readings, potentially contributing to the production and delivery of substandard product. . In manual dial gage testers ASTM correction tables must be referenced to determine the correct factor to adjust by. Alternatively, and in .

The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and understand the standard completely before attempting a Rockwell test. The Rockwell test is generally easier to perform, and more accurate than other types of hardness testing methods .Instron can provide accredited hardness calibrations to the following standards: E-10 Standard Test Method for Brinell Hardness of Metallic Material; E-18 Standard Test Method for Rockwell Hardness and Rockwell Superficial Hardness of Metallic Material; E-92 Standard Test Method for Vickers Hardness of Metallic Material 1kgf to 120kgf

warm vs cold compression test

warrior 350 compression test

Informações valiosas! Gratidão Dr. Samuel!🙏. Sob a ótica de uma medicina voltada para a prevenção de doenças e com uma abordagem totalmente integrativa, o Dr. Samuel Dalle Laste atua de forma a promover saúde através da mudança do estilo de vida, ensinando o paciente sobre os verdadeiros pilares para uma longevidade mais saudável .

rockwell hardness c testing calibration adjustment|rockwell hardness testing machine diagram